Shot blast room is a large-scale enclosed surface treatment facility primarily employed for rust removal, descaling and similar operations on oversized workpieces and irregularly shaped components.

Principal Structural Components of shot blasting room:

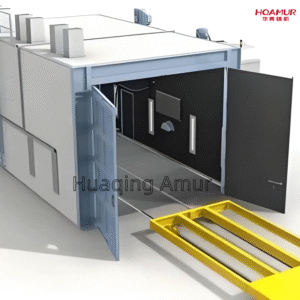

1.Cleaning chamber Struct

ure: The main framework is fabricated from welded structural steel, clad externally with steel plate and internally lined with wear-resistant rubber or polyethylene sheeting to mitigate abrasive impact.

Electric or manually operated sliding doors are fitted with rubber seals to prevent dust leakage.

Explosion-proof lighting with a minimum illuminance of 500 lux is installed within the chamber.

Observation windows utilise double-layered tempered glass.

2.Blasting System:

Gun assemblies comprise manual and automatic variants. Manual guns offer flexibility for irregularly shaped components;

automatic guns are mounted on robotic arms or rails, suited for batch processing.

3.Abrasive Recovery and Separation System:

Recovery units include pit-type and scraper conveyor belt configurations. Pit-type systems utilise grating and screw conveyors for abrasive retrieval; scraper belt conveyors are appropriate for large-scale blasting chambers.

Separation equipment employs vibrating screens or air separators to segregate qualified abrasive, fines, and impurities, with qualified abrasive returned to storage tanks.

4.Dust extraction system: Comprising extraction fans, cartridge dust collectors, and ducting. Fans draw dust-laden air into the collector, where it is filtered through cartridges before clean air is discharged, with dust collected in dust collection bins.

5.Workpiece Conveying System :

Depending on workpiece type, conveyance methods include rail trolleys, roller conveyors, or hooks:

– Heavy components typically use electric flatbed or rail trolleys;

– Long, linear workpieces employ roller conveyors;

– Small to medium components are suspended via hooks.

6.Sandblasting Booth Rail Trolley Conveying System

7.Electrical Control System:

Equipped with an electrical control cabinet employing PLC control to manage operations such as equipment start-up and interruption. Electrical components predominantly utilise renowned brand products to ensure stable equipment operation.

Working Principle

During operation, the sandblasting booth utilises a high-pressure air stream supplied by an air compressor to propel abrasive material from the storage tank through a spray gun onto the workpiece surface. The impact force of the abrasive removes impurities such as rust and scale from the surface.

Workpieces traverse the chamber via the conveyor system, ensuring uniform surface treatment.

Scattered abrasive is collected by the recovery system. After separation, qualified abrasive is recycled back into the storage tank for reuse, while dust-laden air undergoes purification through the dust extraction system.

Performance Characteristics

- 1)High processing capacity: Capable of treating large workpieces measuring tens of metres in length and weighing hundreds of tonnes, suitable for industries such as shipbuilding and steel structure fabrication.

- 2)High Flexibility: Combines manual and automatic spray guns to accommodate processing requirements for workpieces of varying shapes.

- 3)Excellent Environmental Performance: Fully enclosed design and high-efficiency dust extraction system effectively control dust emissions, meeting environmental standards.

- 4)Broad Adaptability: Achieves multiple processing effects including rust removal, polishing, and surface strengthening by switching between different abrasives.