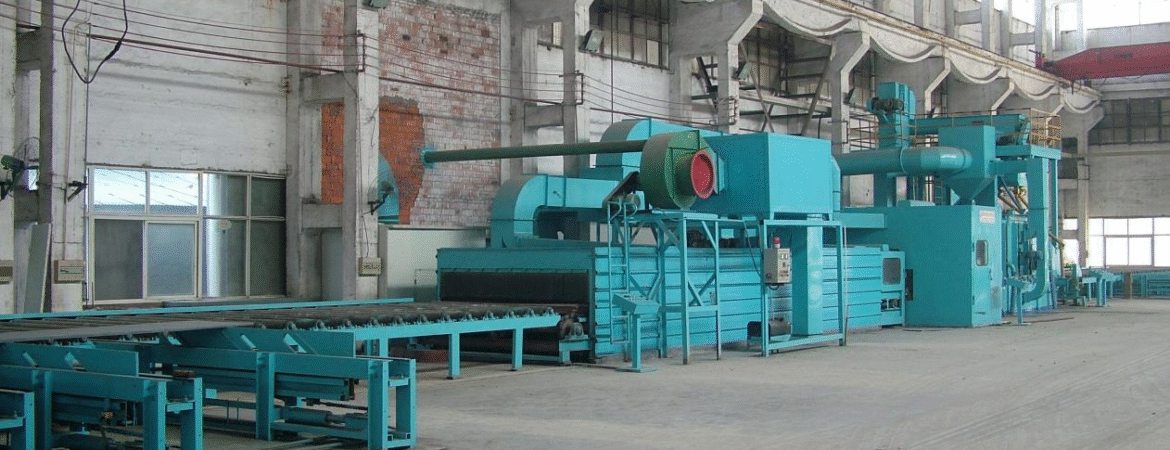

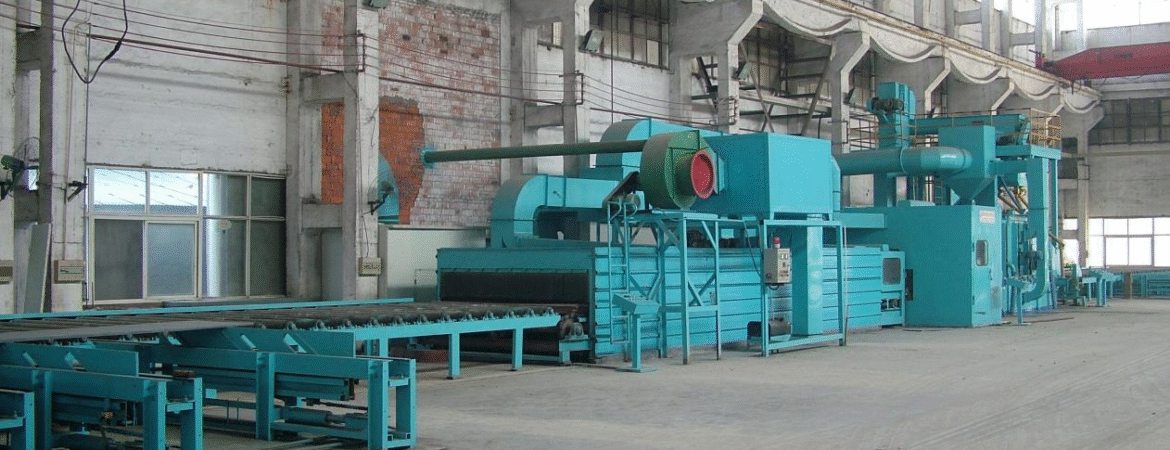

Huaqing Amur recently completed the customised retrofit and commissioning of a heat treatment shot blasting machine for a thick plate line at a major domestic shipyard. Centred around Siemens S7-1500 series PLCs, this production line integrates pre-cleaning preheating, high-speed shot blasting, spray coating with drying, multi-stage dust removal, and intelligent monitoring. It innovatively employs a dual purification process combining cyclone dust collectors with bag filters, achieving over 99% separation efficiency for shot and slag. Dust concentration in the blasting zone has been reduced to below 10mg/m³, fully meeting the ultra-low emission requirements of the steel industry.

Furthermore, the production line’s intelligent monitoring platform enables fault early warning, energy consumption analysis, and remote operation and maintenance, boosting equipment uptime to 99%. The double-sided shot blasting process precisely accommodates processing requirements for plates of varying specifications. Post-commissioning, it has enhanced the surface finish quality of customers’ steel plates by 20%, establishing itself as a benchmark project for green intelligent manufacturing within the steel industry.

Leave A Comment